Best ways to sharpen a knife at home

Content:

- Proper preparation

- Determining the angle of sharpening

- How to sharpen a knife: a review of tools

- Donkey (whetstone)

- Mechanical sharpener

- Electric sharpener

- Musat

- Grinding on abrasive stones

- Sandpaper or fabric

- Sharpener Lansky

- Grinding and grinding machines (sharpener, electric emery)

- Tools at hand

- Verification Methods

- What knives cannot be sharpened on your own?

To learn how to sharpen knives correctly, you need time and some experience. There are many nuances and specific points in this procedure, so each master selects a method according to his personal preferences. But to master the technology in general, so that there are enough skills for elementary operations like sharpening kitchen knives, you can pretty quickly. Consider the basics of this art and give some useful tips.

Proper preparation

Start the sharpening process by determining the material of the blade. If you sharpen a knife without taking into account the characteristics of the alloy from which it is made, the ideal result cannot be achieved.

- The most common at home are carbon steel knives. This alloy of iron and carbon is easy to sharpen. Such products are also inexpensive. The main disadvantage is the tendency to oxidation and the appearance of rust spots.

- Corrosion-resistant steel with a low carbon content and alloying additives (chrome, less often molybdenum or nickel) is not afraid of corrosion, but its hardness is lower. Therefore, products from such an alloy quickly lose their sharpness and need regular sharpening.

- Knives made of high carbon steel alloyed with vanadium or cobalt have high hardness, sharpen well and stay sharp for a long time. They are also not afraid of corrosion. The only drawback of this class of blades is their high cost.

- Damascus steel is used for the manufacture of knives and hunting knives. Such a blade is forged from a package of bars or strips with different contents of carbon and alloying additives. Damask steel products keep sharpening excellent. Sophisticated manufacturing technology and excellent performance determine the high price of such products.

- Ceramic knives remain sharp for a long time. But such a blade is very fragile and can break due to inept sharpening or falling from a height.

If you are trying to sharpen a knife for the first time, take a simple carbon steel kitchen tool for training. If the blade is damaged, it will not cause such damage as if an expensive collection or hunting knife were damaged.

The knife to be sharpened is thoroughly cleaned of contaminants. Then the blade is inspected in bright light. This allows you to identify all the defects: chips, crests, etc. Having examined, you will understand which part of the blade needs intensive sharpening, and which only needs to be slightly corrected.

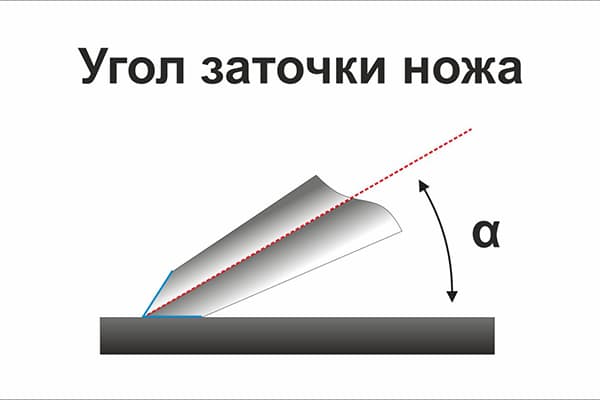

Determining the angle of sharpening

In order for the knife to cut equally well with any part of the blade, it is necessary to achieve the same angle of inclination of the blade along its entire length. The choice of this angle is one of the main points of correct sharpening.

There are two rules:

- The smaller the sharpening angle, the sharper the blade will be.

- The larger the sharpening angle, the longer the knife will not become dull.

The ideal compromise between the sharpness of the blade and the durability of the sharpening is in the range from 25 ° to 45 ° (the value of the angle formed by the two edges of the blade is indicated). To get such an angle, the inclination of the blade to the grindstone needs to be done twice as much. For example, if you plan to sharpen the blade at 35 °, then the knife must be tilted 17.5 ° from the bar.

Too sharpened knife is dangerous for hands, towels when wiping, etc., therefore it is inconvenient to use.For a kitchen knife, sharpening at 40-45 ° will be optimal.

Placing standard angles will help a regular sheet of paper. The angle between the long and short sides of the sheet is 90 °. By bending the sheet diagonally 1 time, we get an angle of 45 °. Repeated folding will give an angle of 22.5 °. With one side of the sheet against the bar, place the blade across the other side of the sheet. The obtained angle should be tried to be kept during the whole grinding process.

How to sharpen a knife: a review of tools

Tool selection for sharpening is the second component of craftsmanship. For thousands of years, mankind has invented many devices that allow you to edit the cutting edge. The type of device is selected based on the goals of sharpening, as well as personal preferences. For a beginner, an ordinary bar from a hardware store is best suited. And in the future, as the skill develops, the turn will come to more expensive and advanced devices.

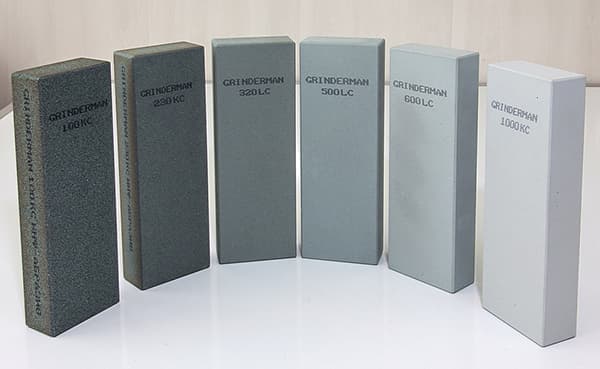

Donkey (whetstone)

Both the rough sharpening and the final fine-tuning of the blade are made with a sharpening bar. The capabilities of each product are determined by the diameter of the solid particles that make up its composition - abrasive grains.

In the household, two bars are needed:

- with large grains - for rough grinding;

- fine-grained - for final grinding.

When choosing the bars, focus on the length of the blade. The bar should not be shorter, but better - 1.5–2 times longer.

Inspect the surface, make sure that there are no chips, depressions or humps on it. The width and shape of the bar does not matter.

Mechanical sharpener

Mechanical sharpeners are produced by both “nameless” companies from China and well-known manufacturers. This device allows you to quickly sharpen the blade, even if there is no skill. But it can only be recommended for sharpening kitchen knives, since the cutting edges will lose their sharpness very quickly. In addition, the need for frequent editing quickly disables the blade. For expensive hunting and collection knives it is better to choose another tool.

Electric sharpener

With an electric knife sharpener, you can achieve high quality cutting edges. Modern models can automatically determine the angle of inclination of the blade, so this machine allows you to sharpen not only a standard kitchen knife, but also fillet knives.

On sale you can find cars, the cost of which varies by an order of magnitude or more. To achieve better results, you should choose more advanced models, not chasing a low price.

Musat

This device resembles a file with a round working part, only its graininess is much less - it's just a core made of strong steel. Musat is included in some sets of knives, and it can also be purchased at a hardware or specialty store.

They don’t sharpen the nutmeg, but only correct the blade, which has slightly lost its sharpness.

Grinding on abrasive stones

Abrasive stones can be of either artificial or natural origin. These are effective tools for sharpening, but they can not be called affordable. Therefore, they are usually bought by professionals seeking to achieve perfect results. They use a grindstone in much the same way as a bar.

Sandpaper or fabric

Sandpaper is glued to a solid base (for example, a wooden block), and then it is sharpened with a knife in the same way as a donkey. Professionals usually dismiss this sharpening method, but for ordinary knives its performance is quite satisfactory.

Sharpener Lansky

This device is convenient for sharpening medium and small blades. It allows you to very accurately withstand the angles of inclination of the edges of the blade, so it is well suited for hunting and collection knives. Two angles simultaneously serve to clamp the blade and set the inclination of the donkey. A whetstone is put on a rod passed through an opening in a corner. Included with the sharpener are several oselok of varying degrees of graininess.

Grinding and grinding machines (sharpener, electric emery)

The principle here is the same: an abrasive wheel (it is made, like a whetstone, from abrasive grains and a binder) is untwisted up to a high speed on the shaft.

The main advantage of sharpening on the machine is the high speed of all operations. But at the same time, it is strongly not recommended for beginners to start with this method: one mistake is enough to irreparably ruin the blade.

Tools at hand

These tools are used to sharpen a knife if there is no bar or other special tool at hand. In skillful hands, even ordinary cobblestones with a flat surface can replace a donkey. Of course, it will not be possible to achieve perfect sharpness in this way, but it is quite possible to return the blade to working condition.

- Second knife

If there are two knives, you can do without any additional tools at all. Knives sharpen each other for 10 minutes, holding one in each hand. After this procedure, the blades will become sharper, and the knives can already be used.

- Glass objects

The rough and rough surface of glass or ceramics is also able to replace the donkey. In the field, sharpening can be corrected about the bottom of a ceramic tea cup, a shard of tile, etc.

- Leather belt

A thick leather belt is usually used for finishing. But if there is nothing suitable at hand, it will help to make the blade slightly sharper and thoroughly dull. The belt must be properly tightened, secured to one end. If you drive the cutting edge along the belt long enough, the blade polishes to a shine and becomes sharper.

To increase the efficiency of polishing, GOI paste will help. A belt with polishing paste added is an ideal tool for finishing dangerous razor blades, sirloin knives, etc.

Verification Methods

The final step in the correct knife sharpening algorithm is to check the sharpness. Many methods of such verification have been known for a long time. Using one or two checks will help to identify flaws in sharpening or make sure the result is perfect.

- On the paper

A sheet of paper (suitable, for example, a sheet from a notebook) is kept on weight. A sharpened knife will cut thin strips without wrinkling the paper. If a cut close to the edge of the sheet does not work, then the blade needs additional refinement.

- On a tomato

A perfectly honed blade, laid on a ripe tomato, will be able to cut it due to its own weight. In addition, sharpening quality can be seen by the thickness of the slices.

Instead of tomato, boiled potatoes are suitable as a test object.

- Hand Hair Testing

This method has long been trusted by sharpening experts. It is believed that if you sharpen the knife well enough, it can be used instead of a razor. Shaving quality indicates the quality of the sharpening.

What knives cannot be sharpened on your own?

Finally, we will tell you about which knives it is better not to sharpen on your own.

The most difficult types of knives to sharpen:

- Ceramic knives. For sharpening, you can not use ordinary whetstones and grindstones. These superhard blades are sharpened on diamond bars, which are rarely found in the arsenal of amateurs.

- Damask steel, damask steel - difficult to sharpen material. Sharpening a damask knife with an ordinary bar is very long and laborious, and when sharpening on a diamond bar, the heterogeneous blade will crumble.

- Blades with a sawtooth edge generally do not provide for re-sharpening. The only thing that can be done with such a knife is to sharpen it on a regular blade (if the quality of steel and the shape of the blade allow).

Beginners are also not recommended to undertake sharpening of their favorite knives (souvenirs, convenient samples, etc.). If the skill is not high enough, there is a considerable risk of damage to the blade.

From the outside it may seem that mastering the sharpening technology is too difficult.However, if you get down to business with patience and without unnecessary haste, it is quite possible to master this skill. And then your knives and other cutting tools will always be in excellent working condition.