How to clean the gun for polyurethane foam, so as not to disable it

Foam is used in construction as a reliable sealant, a good noise and heat insulator, fixative, which fill cracks and cracks in the walls, roof, etc. foam is professional and household. The latter is sold in a cylinder already equipped with a gun, usually plastic and disposable. For professional foam, a special, reusable device is used.

Cutaway

Foam is fed through a device called a gun, similar to a firearm. Like its namesake, the mounting gun has:

- barrel - a hollow tube with an internal coating of Teflon;

- trigger (trigger) - a lever that opens the valve so that the foam leaves the bollon and enters the barrel;

- handle - part for convenient holding of the device in one hand and the direction of the muzzle.

Also, the mounting gun has parts specific to it:

- feed regulator;

- threaded adapter for installing a bottle of foam or cleaner.

There are non-separable, partially collapsible and completely collapsible designs of such pistols. The latter allows you to well clean the device of the remnants of foam, change the worn part - are the most practical, but also the most expensive.

During assembly, plastic and metal parts are used. This should be considered when buying. Plastic parts make the device easier, but wear out faster and fail under the action of solvents and chemical components of the sealant. The pistol will last longer, in which metal components predominate.

Tip

Metal parts are easier to clean and more resistant to the aggressive environment of both the foam itself and the cleaner. But plastic spare parts will become worthless.

Cheap guns for polyurethane foam, usually made in China, usually do not pay off. Due to the design features, low-quality parts, the foam hardens quickly, air escapes from the cylinder, and after cleaning they simply break. Therefore, it is worthwhile to find out the reviews of professionals about reliable manufacturers of high-quality pistols.

When and how to clean

Using a professional pistol is convenient in that it is a reusable device, although not cheap. Experienced installers believe that the device pays off in 3-4 cylinders.

After application, a certain amount of foam always remains in the tube - how to clean it? Remove the remaining foam immediately and do not wait until it hardens - otherwise it will be more difficult to do. There is a special cleaner to remove foam from the barrel. You need to purchase it with her, preferably the same brand. The cleaner is screwed onto the thread instead of the foam balloon and, after pressing the trigger, is fed into the barrel. The remaining foam is easily removed.

Important

Like any hand tool, a foam gun needs proper care. Otherwise, he will not last long.

If the foam from the cylinder is not fully used and suitable for further use, then it remains bolted to the gun. If you remove it, then the foam remaining in the gun will dry very quickly. The purifier is used after the cylinder is empty or air has escaped.

In terms of chemical composition, such cleaners differ from one manufacturer to another, but they have the same function. This substance is quite toxic, if it gets on the surface of the hands and mucous membrane, there may be a burning sensation, irritation. It is necessary to wash the cleaner thoroughly with soap and water, and if it gets into your eyes, consult a doctor.

Some companies produce cleaners for non-hardened and hardened foam. When buying, you need to pay attention to this.

Methods and features of cleaning

The methods and features of cleaning the gun for polyurethane foam depend on the degree of contamination.

The easiest way is applied when the contamination is removed immediately after use. It is described above, it consists in mechanically cleaning the outer surfaces and pushing the remaining foam from the barrel using a special cleaner.

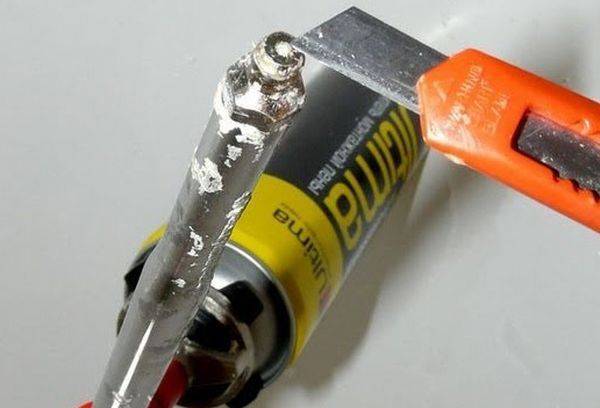

The second method is used if the barrel is completely blocked and the trigger cannot be pulled. In this case, you need to be careful not to scratch the barrel, clean it of foam at the base and drop it with solvent. At the same time, lower the trunk down. After a few minutes, the trigger mechanism will begin to operate, you can continue cleaning further.

If the trigger has not become movable, then the third method is used. In the place where the foam is wound on the gun, there is a small ball. The solvent must be applied to it. This should help clean up if the foam clogs the valve. After 15-20 minutes, a cleaner must be installed on the gun, the barrel must be cleaned with it, pieces of foam should fly out.

When the gun is completely clogged with hardened foam, it will require disassembly and mechanical cleaning of the parts. This should be done only if there is an idea about the device device. Otherwise, you need to contact specialists.

It is necessary to remove all collapsible parts, the barrel can be cleaned with wire and acetone. The remaining parts are cleaned of contamination with a rag and solvent. This is an extreme case. It is not worth bringing equipment to it. Foam, even after cleaning, can be fed poorly, hard, and the gun will be unusable.

Thus, starting repairs, installation using a foam gun, you must have a can of cleaner. This will help to timely clean an expensive tool from the remains of not yet frozen foam, to extend its life.

Otherwise, the foam has time to harden completely and fulfill its purpose as a sealant, but already for the gun. When using brute force, the Teflon coating inside the barrel is broken, and the gun becomes unusable.

Tip

If cleaning the gun for polyurethane foam is carried out using white spirit or acetone, then their contact with plastic parts is undesirable.

At the end of the cleaning of parts (if it was disassembled), it must be assembled, rinsed again with a cleaner from the can and wiped dry. So the gun will be ready for next use.

Conclusion

If the gun for applying polyurethane foam is often used, it serves to make money, then you should take care:

- About choosing a quality tool from a trusted manufacturer.

- That the design was collapsible and with a predominance of metal parts.

- To buy a cleaner of the same brand together with a foam bottle.

- To clean the tool immediately after use, without waiting for the solidification of the solid substance.

By following these simple rules, you can significantly extend the life of the gun for mounting foam and quickly recoup the cost of its acquisition.