How to reliably glue joints on linoleum?

Content:

Linoleum is considered to be the most demanded flooring. The impressive variety of colors and sizes, the practicality and quite budgetary cost of this material make it indispensable in the decoration of private apartments and public spaces. To carry out the laying of the coating at home, it is not necessary to be a specialist. It is enough just to accurately do the work and know how to glue linoleum so that the joints are durable and invisible. The use of hot or cold welding will provide a reliable and beautiful connection between the sheets of material.

When do you need to glue linoleum?

Linoleum is a finishing material made from natural or polymer fibers. Laying such a floor covering will not be difficult if you only know how to glue linoleum end-to-end at home.

The fact is that this finishing material goes on sale in the form of rolls 2 or 5 meters wide. There are no other options. If the room in which the repair is planned has a small area and you can cover the entire floor with a whole piece, there are no difficulties.

But much more often the rooms do not differ in the correct form or the width of the room is more than 5 meters. In such cases, it is necessary to cut and lay several pieces of linoleum, which then need to be securely and seamlessly fastened together. If this work is done poorly, water will penetrate the joints, dirt will clog, and after a while the edges of the canvases will bend and twist.

It is necessary to glue linoleum in doorways and when replacing a damaged piece with new material. If the flooring has a pronounced pattern or the designers decided to decorate the floors with colorful applications, it is also impossible to do without gluing joints.

How can linoleum be joined at the joints?

To connect two or more pieces of linoleum into one whole, you can use the following methods.

- Sticking double-sided tape. This option is more suitable for creating a temporary coupling, and its main advantage is the speed of work. The resulting seam will soon disperse, debris and dust will fall into it.

- Installation of aluminum or plastic nut. A good way to create a quality connection, however, it is appropriate to use it only in doorways.

- Hot welding. Bonding parts of linoleum by hot welding is used when laying industrial flooring in public areas. This method requires professional equipment and skills, so it is unsuitable for connecting household coverage at home.

- Cold welding. A special glue called cold welding is used to connect the canvases and create an airtight seam.

In everyday life, the last method of gluing linoleum is mainly used.

Hot welding method

Hot welding is most often used when laying industrial linoleum, which differs from household finishing material in thickness, strength, wear resistance. Such flooring is laid in schools and hospitals, offices and industrial premises, that is, where there is an intense mechanical effect on the floors.

To get a high-quality and aesthetic seam, before gluing linoleum together, it is necessary to glue the PVC coating to the floor. Joint sealing can begin no earlier than one day after gluing.

For bonding ordinary linoleum, hot welding is almost not used. The fact is that a conventional coating has a small thickness and does not withstand those temperatures that are used for joining by heating. In addition, for carrying out hot welding it is necessary to have professional equipment and certain skills.

The following materials and devices are required for hot-docking:

- special hair dryer;

- a cord made of linoleum;

- sharp knife or flat chisel.

To create a strong and reliable seam, you must perform the following steps.

- Along the entire length of the joint (the sheets should be laid with a minimum gap and firmly glued to the base), a groove is cut with a chisel, into which the cord will be placed in the future.

- The docking point is cleaned of dust with a vacuum cleaner.

- The cord from linoleum is tucked into the holder of the welding gun, which is included in the network. A connecting cord can be purchased with flooring.

- Under the influence of air heated to 400 ° C, the edges of linoleum together with the cord melt and join. The result is a durable and almost imperceptible seam.

- The part of the cord towering above the junction can be cut with a sharp knife.

At first glance, the hot welding procedure seems very simple, but in fact it is not. When carrying out such work, professional skills are required, in addition, high-temperature welding is a danger to the life and health of an inexperienced repairman.

Features of cold welding

To glue the coatings at home, they use reaction adhesives, which are also called cold welding. In their composition they contain polyurethane and epoxy resin, have a very corrosive smell and are flammable.

The reaction glue reacts chemically with the polyvinyl chloride of which the flooring is made. The edges of the joints soften and dissolve in each other, as a result of which a thin but strong seam is formed, resembling a real weld in appearance. This adhesive is especially important when laying a coating on a foam basis, since it is not recommended to use hot welding for such materials.

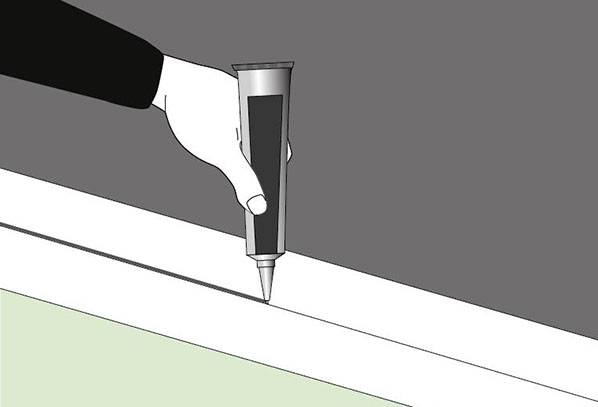

Cold welding is sold in tubes equipped with a special nozzle-needle, with the help of which the adhesive enters the most inaccessible places and allows you to firmly and firmly glue the joints of linoleum.

Cold welding has many advantages.

- Any novice master will be able to cope with the work of laying flooring using cold welding, since the method does not require skills.

- Ideal not only for laying new linoleum, but also for repairing old coatings.

- No special equipment is required, due to which the cost of finishing work is significantly reduced.

- The seam obtained by cold welding is monolithic, accurate and durable.

Bonding joints of the flooring by cold welding does not require physical effort.

Types of glue

There are several types of adhesive used as cold welding. The choice of suitable glue depends on the composition and type of finishing material, as well as on the nature of the work performed.

- Type A

When laying new linoleum, type A cold welding glue is used. Due to the high solvent content, this adhesive has the most liquid consistency in comparison with other similar compositions, so it is advisable to use it to create joints with a width of no more than 2 mm. The main advantage of A-type glue is that the resulting seam is almost invisible and at the same time incredibly durable. The glue is best suited for solid linoleum with perfectly even edges.

- Type C

This adhesive composition has a rather dense consistency and is used for sealing joints with a width of 3-4 mm. Type C glue is used to glue the canvases of the old coating that have separated from each other.Type C cold welding not only glues the web together, but also fills the gap, as if creating an intermediate strip of linoleum.

- Type T

Lovers of this type of adhesive are rarely used. However, professionals use it to connect PVC and polyester webs.

How to seal linoleum with cold welding?

The technology of joining the flooring with the use of cold welding is not particularly difficult. The main thing is to carefully follow the instructions and carefully perform the work at each stage. Before gluing linoleum end-to-end at home, you must prepare type A glue, adhesive tape, a knife, gloves.

Important!

Drops of glue should not be allowed on the surface of the coating.

In order not to stain linoleum with glue and not to plant a blot, which will be very difficult to remove, you must always use a soft rag. Opening and closing the tube with glue, you need to hold it over this rag, protecting the floor from falling drops. If, nevertheless, a drop of glue remains on linoleum, it is better to wait until it is completely dry and remove the dry film with a knife.

Work on gluing joints should be carried out with gloves and with windows open, since the glue has a pungent unpleasant odor.

- Before sticking joints, the first thing you should do is prepare them for connection - get wet with a rag, remove dust and debris that has accumulated in the cracks with a vacuum cleaner.

- The place of the future joint is protected by masking tape. This is necessary in order to protect the edges of the paintings from glue.

- With a sharp knife, the adhesive tape is cut directly above the joint.

- On the tube with glue put on the nozzle-needle and squeeze the composition into the gap between the canvases. Squeeze out the adhesive so much that it protrudes 4 mm above the surface of the material.

- After 15-20 minutes, the adhesive tape is removed.

- You can operate the finished flooring after an hour after the end of the work.

A perfectly flat floor is extremely rare. There will always be slight bulges and hollows. If you make one long seam, then in uneven places it will puff. Therefore, experts advise gluing the joints in small segments up to 70 cm long. Moreover, the new section should be glued only after the previous one has dried. If you follow this technology, the seam will be more even and invisible.

When repairing linoleum, a thicker type C glue is used, so sticking adhesive tape is not necessary. In the rest, the process of joining canvases completely repeats the measures described above.

Sticking linoleum at the joints at home is not difficult. The cold welding method will allow you to create a tight, durable and aesthetic seam, and this does not require special equipment or professional skills. The main thing is to choose the right glue and do the work accurately, without deviating from the instructions.