What glue is suitable for working with PVC products

Content:

Polyvinyl chloride is widely used for the production of building materials, sewage systems, boats and camping equipment are made from PVC. A good glue for PVC does not lose its properties for several years, is not affected by moisture or liquid, does not crumble, does not change color and structure.

There are two types of glue for PVC:

- one-component composition, completely ready for use;

- two-component adhesive - an adhesive composition and a separate hardener are included in the kit. Before use, both components are mixed.

It is cleared that a two-component adhesive for PVC provides a more durable and reliable seam. But single-component types are easier to use, even inexperienced craftsmen can easily handle them.

Also, when choosing a suitable adhesive for PVC fabric, film or building materials, the main factors should be considered:

- the purpose of the application is the connection of parts, the laying of finishing materials made of PVC, the repair of inflatable boats or sports and tourist equipment;

- degree of moisture resistance;

- temperature limits for application and use;

- adhesion to various surfaces;

- plasticity of the composition, ease of application on various surfaces.

How to glue PVC: an overview of the compositions for different types of substrates

There are several types of composition for bonding products made of polyvinyl chloride. Glue for PVC is chosen depending on the type of material - it can be fabric, finishing materials, film, communication systems (strong and hard material).

Distinguish types of glue by their properties.

- Adhesive glue - provides exclusively fixation of elements, but does not stick. It is used for laying floor coverings, the absence of a durable seam simplifies the dismantling of fragments or the entire coating.

- Reaction adhesives effective when laying heavy rubber elements or joining large parts.

- Contact adhesive provides the most durable seam and crystallizes quickly enough.

Laying tiles, wall panels

Lining the surface with PVC panels requires high elasticity, resistance to moisture and temperature changes from the adhesive. If the surface is smooth, the glue is applied directly to it, otherwise, a reinforcing mesh should be applied, one can not do with one glue.

For the installation of plastic panels, special glue “Liquid Nails” is on sale, the products of the company “Titan” and the long-established “Moment of Installation” are no less popular.

PVC tiles are laid in a similar way, but the purpose of the room plays an important role here. Some masters neglect the choice of glue according to the type of room, which leads to a poor-quality result - the fragments “move out”, lag behind the base.

Dealing with the appointment is quite simple: if high traffic is expected, it is better to choose an epoxy or polyurethane composition, for the home, the main factor will be water resistance and toxicity. Acrylic and polychloroprene glue have the lowest emission of volatile compounds. The compositions are presented in a wide assortment, they are used for gluing to a varnished base, for fastening cork products, including wall and floor finishes.

PVC materials

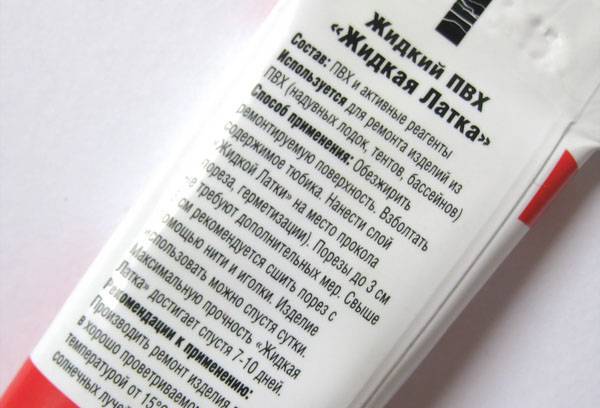

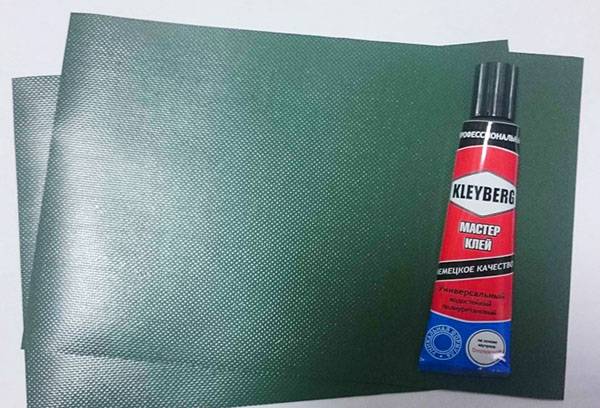

PVC fabric is used for the manufacture of boats, camping tents or similar products. During operation, the material may get damaged, and the composition included in the repair kit is enough only for a minimum cut.

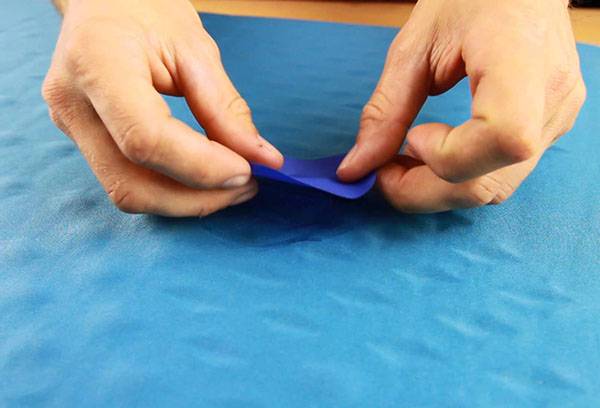

To glue the fabric, use various thermoplastic compounds, silicone threads. After application, the composition is gently heated without damaging the material itself. Glue for PVC fabric is distributed over the area, then subjected to high temperature using an industrial hair dryer, after which the composition “welds” the fabric parts. The most effective method is to patch with a similar material and use a suitable adhesive.

Film

PVC film is used on an industrial scale - for facing furniture, doors, pools. In the particular case, there may be a need to repair or restore part of the element: attach or replace the peeling material.

For such purposes, it is best to purchase a two-component adhesive for PVC film with a suitable indicator of heat resistance. Not all formulations can withstand direct sunlight (this is important in the case of pool trim). When repairing interior doors, the temperature regime will be in second place, it is more important to pay attention to the degree of moisture resistance.

Instructions for use

In practice, the use of glue for PVC is not significantly different from the use of other compositions for joining materials. However, when carrying out work, certain rules should be adhered to.

- According to the technology, any surface should be degreased with White Spirit, cleaned of dust or other contaminants.

- Durable plastic elements are glued together with compositions based on vinyl chloride polymers, rubber or PVC fabrics are glued with thermoplastic types of specialized glue.

- The adhesive composition is applied in a uniform layer.

- For effective setting, the seam is always exposed to elevated temperature.

- The compound is not subjected to any load for 24 hours.

The selection of a suitable adhesive largely depends on the physicochemical properties of the material to be bonded. Some types of PVC are unstable to aggressive liquids, therefore, the adhesive should not contain solvents.

Popular brands and their cost

The brand “Moment” is very popular among users. The manufacturer offers a wide range of different types: glue for boats, "Crystal Moment", gel, rubber. The products are of high quality, which is also reflected in the price - a tube for 30 g of glue costs about 50-60 rubles.

No less wide lines of glue for PVC for various purposes are produced by Soudal. For a fairly affordable cost (150-200 rubles), the user can choose the glue of any highly specialized purpose.

To connect solid structures, craftsmen are often advised to purchase "Second" cold welding. Also in the line of adhesives there are excellent types for joining soft materials.

When carrying out a large amount of work, the Thomsit brand will be the best choice. The manufacturer suggests choosing a two-component polyurethane composition suitable for PVC in a container of 5-7 kg, the price is relatively low, about 1500 rubles, which is very profitable. The glue does not contain toxins, does not emit harmful substances and solvents.

Thus, choosing glue for PVC is not such a difficult task. It is worth focusing on the type of surfaces to be glued, the operating conditions and the price category of the product.