The choice of glue for facing with natural or artificial stone

Content:

Strength and durability of stone cladding largely depend on the quality of preparation of the base and the correct choice of adhesive composition. Glue for stone is represented by a wide range, allowing you to choose the best option for installing tiles from natural material, porcelain stoneware, clinker or other decorative and protective coatings.

The suitability of the adhesive component for this work is determined by several mandatory conditions.

- First of all, this is the correspondence of the characteristics of the base and the facing material itself.

- The choice is influenced by the features of the recommended installation technology.

- Also, the conditions under which the tiled coating will be operated must be taken into account.

It is not recommended to buy glue from a little-known manufacturer, with an expired shelf life or the integrity of the branded packaging. By the end of the storage time, the performance of the dry adhesive mixture is reduced by 12-15%.

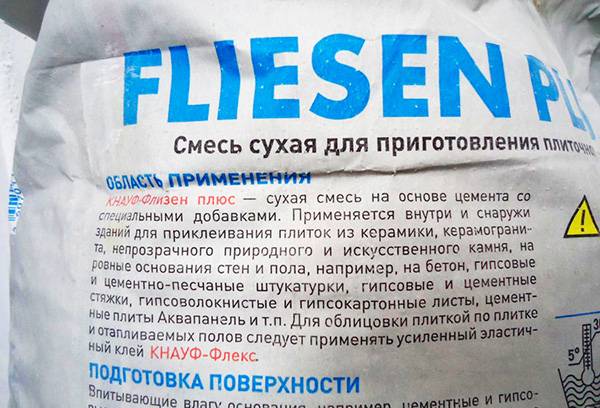

Leading adhesive manufacturers

A review of the characteristics of modern adhesive compositions will tell you how to choose a material that, in terms of cost and performance, meets all the stated requirements. In the market of building materials, glue for stone and artificial tile coatings is represented by a wide range. Domestic and foreign manufacturers offer more than a hundred types of adhesive compositions of different cost and for different purposes.

Most often, when tiling, a two-component adhesive composition is used, which in the standard version is a dry cement-sand mixture with polymer additives.

The list of the most demanded products is dominated by popular compositions for various types of tile-mounting works of the following brands:

- Ceresit;

- Bergauf;

- Knauf;

- Eunice

- Weber-Vetonit;

- Litokol

Exact observance of the sequence of preparation of the working solution allows you to use the capabilities of these materials with high efficiency.

Important!

The technology provides for thorough mixing of the solution with a construction mixer or a nozzle of a household electric drill until a homogeneous structure is obtained. Failure to do so may adversely affect the performance of the adhesive base.

Technical characteristics of adhesives

The glue for natural stone or its artificial counterpart, used for interior cladding, shows its best qualities with standard humidity, low loads and moderate temperature extremes.

Among the advantages of such tools:

- moderate cost and excellent installation properties;

- compliance with environmental standards;

- good ductility;

- good frost resistance (F75);

- excellent adhesion;

- lack of smell and allergenic factors.

The life of the adhesive components of tile coatings, depending on the quality of the starting material, is from 30 to 50 years.

Features of external use

The problem lies in the different coefficients of thermal expansion of the material of the walls and facing materials. The combination of temperature and humidity differences, vibration from passing vehicles present quite stringent requirements for the adhesive base of tile coatings.

The operating parameters of adhesive compositions for tiled outdoor work suggest resistance to adverse influences. Glue for natural stone, designed for use in difficult, and even extreme conditions, is characterized by special properties:

- elasticity and moisture and frost resistance appropriate to the climate of the region;

- resistance to shock and local loads;

- neutral reaction to chemical and biological effects;

- excellent adhesion and mechanical strength.

For the installation of marble tiles and other hygroscopic materials, adhesive anhydrous adhesive mixtures based on epoxy are recommended.

Advantages and disadvantages of two-component compositions

Almost every two-component adhesive is much more advanced in its capabilities than a simple one-component analog.

- The two-component cement-polymer-based stone glue fully meets the requirements of SNiP.

- Adhesive mixtures of acrylic polymer and hardener are characterized by quick setting, a wide selection of shades and increased strength of the joints.

- Glue for stone, created on the basis of epoxy resins and polyurethane, is characterized by high ductility, frost resistance and increased strength, therefore, it can withstand the weight of heavy plates.

- The dry mixture in a separate container maintains its working properties during long-term storage.

- A working solution can be prepared immediately in an amount sufficient to carry out all the work.

The main disadvantage of single-component dry mixes is the deterioration of performance during prolonged storage in adverse conditions.

Important!

The finished cement-polymer mortar is suitable for work before hardening. For different types of glue, this time varies from 30 to 50 minutes. After this time, performance is not restored by adding water and stirring.

Which glue is better to use for artificial stone?

The glue for artificial stone, slightly different in recipe and cost, allows you to get a strong connection of tiles with any mineral, brick and concrete substrates.

The practice of installation and operation of tile coatings shows that the independent improvement of the performance of a standard concrete mortar base by adding polymer components is not economically effective.

Let's consider the main advantages of glue for a stone of synthetic origin.

- Simplified, affordable for do-it-yourself installation is appreciated by home craftsmen.

- Prefabricated compositions are characterized by a wide range of additional parameters, including resistance to local loads and other adverse factors.

- In the evaluation of adhesives, the compatibility and adhesion of the material with concrete and brick structures is of no small importance.

For the installation of large-format porcelain and clinker tiles, the following brands of adhesive are successfully used:

- Anserglob BCX;

- Ceresit CM 17 Super Flexible;

- Baumit Basic.

For work with acrylic tiles, Trans Stone glue is recommended, with Qui composites ConfiAd glue is perfectly combined.

Tip

When buying glue on market collapses, the risks of acquiring counterfeit products increase. Unfortunately, a significant part of it is sold under the trademarks of bona fide manufacturers. The problem is solved by placing an order at sales offices or specialized company stores.

New and time-tested tile adhesives have a certain versatility in use, but when choosing a working material for yourself, first of all, its installation and operational properties should be taken into account.